Explosion-proof, anti-corrosion centrifugal fan

4-72; B4-72, F4-72 explosion-proof, anti-corrosion centrifugal fan

1. Application

The 4-72 centrifugal fan can be used for indoor ventilation in general factories and large buildings. Transport air and other gases that are not spontaneously combustible, harmless to the human body, and non-corrosive to steel.

The B4-72 fan can be used for ventilation of flammable and volatile gases. There must be no viscous substances in the gas, and the dust and hard particles contained in it should not exceed 150mg/m3. The gas temperature should not exceed 80°C.

The performance, options and foundation dimensions of the B4-72 fan are consistent with those of the 4-72 model, and can be selected according to its sample. The structure of the fan is basically the same as that of the 4-72 type. No.2.8-6A adopts the B35 type motor with flanges and feet. The No.6-12C and D motors use the YB series corresponding to the Y series in the table. The form is B3.

The F4-72 fan is made of stainless steel and glass fiber reinforced plastics for transporting corrosive gases, and its performance and foundation size are the same as those of the 4-72 type.

Two, the form

Viewed from the side of the motor, the Falun rotates clockwise, which is called a right-handed fan, which is represented by "right"; the impeller rotates counterclockwise, which is called a left-handed fan, which is represented by "left".

Fan outlet location. Indicated by the air outlet angle of the casing. 4-72 type fans No. 2.8-6 are made into N types when they leave the factory, and the user can install them in the required positions according to the requirements. No need to specify when ordering. The adjustment range of the No. 2.8 air outlet position is 0°-225°; The interval is 45°. NO.3.2-6 The adjustment range of the air outlet position is 0°-225°, and the interval is 22.5°. NO.3.2-6 The adjustment range of the air outlet position is 0°-225°, and the interval is 45°. NO.16 and 20 air outlet positions are fixed in three types: 0°, 90°, and 180°, which cannot be adjusted and must be specified when ordering.

There are four kinds of fan transmission modes: A, B, C, and D. Among the 4-72 fans, NO.2.8-6 adopts A-type transmission, NO.8-12 adopts C and D-type transmission, and NO.16-20 adopts Type B transmission.

3. Structural features

Among the 4-72 fans, NO.2 8-6 is mainly composed of impeller, casing, inlet wind and other parts with direct-connected motor. NO.8-20 has transmission parts and so on besides the above parts.

(1) The impeller is composed of 10 backward inclined blades, a curved front disc and a flat rear disc. Made of copper plate or cast aluminum alloy, and corrected by dynamic and static balance, the air performance is good, the efficiency is high, and the operation is stable.

(2) The casing is made into two different types. The NO.2.8-12 casing is made as a whole and cannot be disassembled. The NO.1-20 casing is made into three openings. In addition to being divided into two halves along the middle horizontal plane, the upper half is vertically divided into two along the center line. Half, connected with snails.

(3) The air inlet is made as a whole and installed on the side of the fan. The cross-section parallel to the axial direction is in a curved shape, so that the gas can enter the impeller smoothly with less loss.

(4) The transmission part consists of a main shaft, a bearing box, a rolling bearing, a pulley or a coupling.

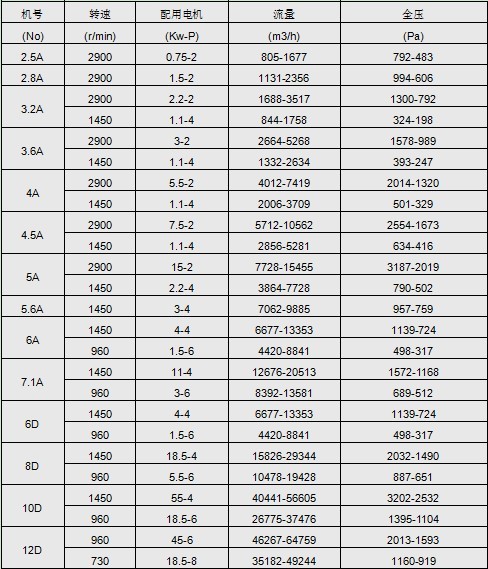

4. Some performance parameters

For more details about the specifications and prices of 4-72 centrifugal fans , please consult customer service .